Contact us

-

3270 Evergreen Dr NE

Grand Rapids, MI 49525 - 616.475.4225

- hello@mutuallyhuman.com

Get in contact

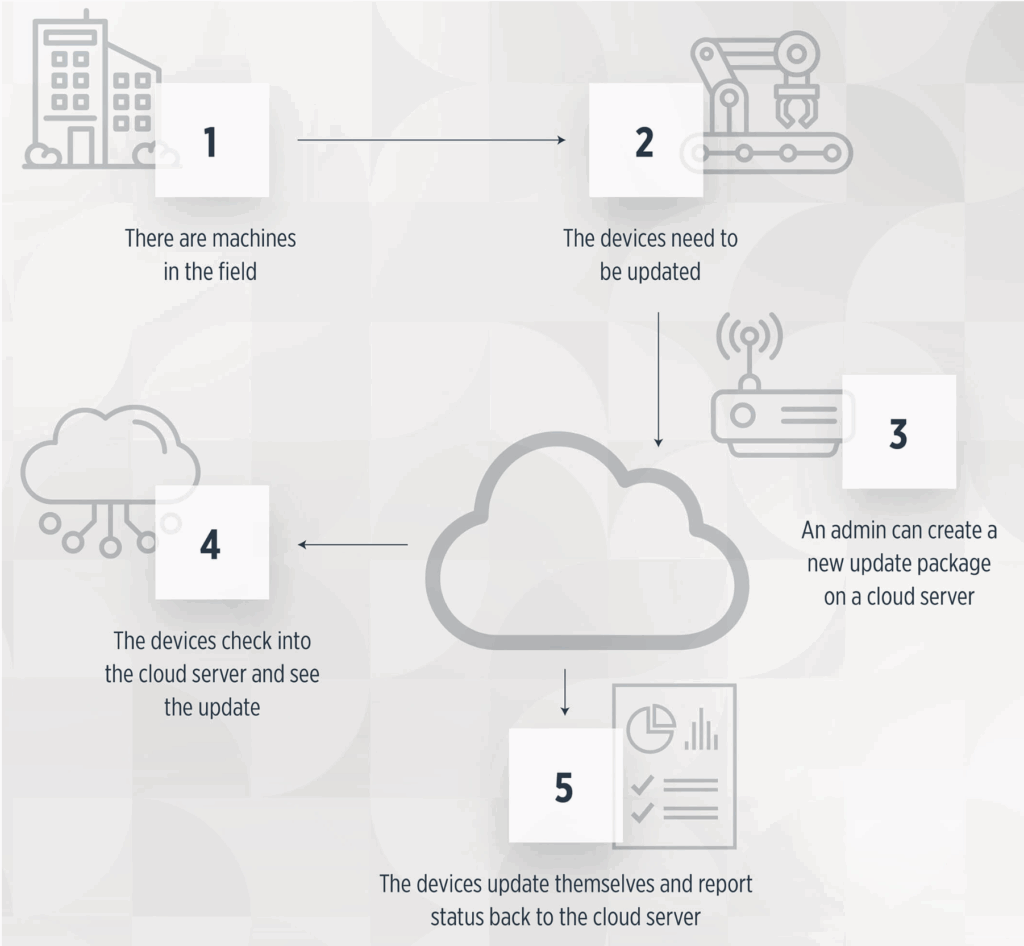

They needed a software partner experienced in developing a cloud-based tech stack that could push over-the-air (OTA) software updates to send UI updates and new features without manual on-site work. In addition, they needed expertise in finding the best way to view machine logs for remote troubleshooting.

Let’s talk about your unique challenges and explore how we can craft a solution that fits your needs. Whether you’re looking to streamline processes, innovate with new technology, or bring a bold idea to life, our team is here to help. Reach out today and take the first step toward turning your vision into reality with a trusted partner by your side.

Contact us

Get in contact

Mutually Human © 2024 | All rights reserved | Privacy Policy | Site Map